| Douglas has been featured in, Business Week Online as well as Greenwich Magazines |

Frequently Asked Questions:

1. How is modular building different from conventional building ?

The structure is built in fairly complete sections that can be shipped by

truck to you building site. Maximum widths of the modules range from

14 to16 feet wide and maximum lengths range from 64 to 75 feet

depending on State regulations. Many other building technologies are

incorporated into the roof systems.

2. What are the benefits of modular building over conventional stick

building ?

Better precision building and better quality control when built in a

factory. Materials are out of the natural elements. Building material theft

is reduced as much of the structure comes complete.

3. Is modular building less expensive than conventional stick building ?

Yes. generally 10 to 20 % less expensive and in time, this will only get

better.

4. Is modular building much faster than conventional stick building ?

Yes. Surprisingly most homes can be built in less than 3 to 5 days at the

factory. It could take 30 to 45 days to be scheduled to built based on

factory backlog. During this time, the site can be prepared by the

Builder to receive the modules. Once the modules are 'set' on site, the

builder will be able to complete the project.

5. How long does a modular home take to build ?

Total construction time can be as little as two to three months.

Conventional building could take as much as 9 to 12 months.

6. Is the quality better in modular building than stick building ?

Yes. Modules are built more precisely with machine tools in a factory

environment. Gypsum board panels are foam bonded and screw fastened

to wall and ceiling framing. The use of oversized gypsum board panels

avoids butt end seams common in site building. The modules are

over-designed structurally to withstand the rigors of shipping.

Redundant structural systems provide reduced sound

transmission between floors and yield a superior product.

7. Critics say the modular homes look boring and unattractive.

It does not have to be. The business model for factory built housing was

simple basic housing for only the price conscious customers. Most

factories do not employ professional architects for in house design

services. Review the home plans offered by most factories and then take

a look at ours.

8. What role does the architect play in the design of modular homes?

Architects that understand the parameters of modular building system

technology are capable of creating almost any style of architecture or

size home. In certain cases we use a hybrid of modular technologies

combining stick-built and panelized construction to achieve the required

high end look.

1. How is modular building different from conventional building ?

The structure is built in fairly complete sections that can be shipped by

truck to you building site. Maximum widths of the modules range from

14 to16 feet wide and maximum lengths range from 64 to 75 feet

depending on State regulations. Many other building technologies are

incorporated into the roof systems.

2. What are the benefits of modular building over conventional stick

building ?

Better precision building and better quality control when built in a

factory. Materials are out of the natural elements. Building material theft

is reduced as much of the structure comes complete.

3. Is modular building less expensive than conventional stick building ?

Yes. generally 10 to 20 % less expensive and in time, this will only get

better.

4. Is modular building much faster than conventional stick building ?

Yes. Surprisingly most homes can be built in less than 3 to 5 days at the

factory. It could take 30 to 45 days to be scheduled to built based on

factory backlog. During this time, the site can be prepared by the

Builder to receive the modules. Once the modules are 'set' on site, the

builder will be able to complete the project.

5. How long does a modular home take to build ?

Total construction time can be as little as two to three months.

Conventional building could take as much as 9 to 12 months.

6. Is the quality better in modular building than stick building ?

Yes. Modules are built more precisely with machine tools in a factory

environment. Gypsum board panels are foam bonded and screw fastened

to wall and ceiling framing. The use of oversized gypsum board panels

avoids butt end seams common in site building. The modules are

over-designed structurally to withstand the rigors of shipping.

Redundant structural systems provide reduced sound

transmission between floors and yield a superior product.

7. Critics say the modular homes look boring and unattractive.

It does not have to be. The business model for factory built housing was

simple basic housing for only the price conscious customers. Most

factories do not employ professional architects for in house design

services. Review the home plans offered by most factories and then take

a look at ours.

8. What role does the architect play in the design of modular homes?

Architects that understand the parameters of modular building system

technology are capable of creating almost any style of architecture or

size home. In certain cases we use a hybrid of modular technologies

combining stick-built and panelized construction to achieve the required

high end look.

9. Can a modular home be custom designed ?

Yes. In this case however, the use of an architect is critical. We can create professional plans and layouts specific to your requirements. We will develop a look

that is stylistically correct creating the greatest resale value possible.

10. What styles of architecture can be created ?

Virtually all styles. Colonial, Victorian, Contemporary, Mediterranean, Avant garde Contemporary, Dutch colonial, Georgian, Shingle style and any other style

desired.

11. What kinds of materials can be specified ?

Nearly everything available in conventional building can be used in modular. If the factory can not get the product in time it can be installed on site.

12. Does union labor build modular homes ?

At many of the factories they do.

13. Are there any size limitations ?

No. The final design can be as big as you like. We developed a design for a 14,000 sf modular home comprised of thirty two modules units in Greenwich, CT.

Most large homes we design range in size from 4,000 to 6,000 sf, consisting of ten to twelve modules. Large open rooms are achieved by setting boxes side by

side, structured to provide an open and inviting living area.

14. Do modular homes have basements?

Yes. In addition, modular homes can be built over crawl spaces, on slabs or even on piles. These

foundation structures should be designed by a licensed architect or engineer.

15. How are the modular units shipped ?

The modules are shipped on carriers, towed by trucks. These trucks require 'wide load' escort vehicles. The modules are weather tight, wrapped in a waterproof

membrane.

16. How complete are they when they arrive at your site ?

As much as 80 to 85% complete. Most modules have interior walls and ceilings finished and primed, ready to receive paint. The electrical and plumbing systems

are installed. Windows, exterior and interior doors are hung, interior trim, cabinetry, toilet fixtures, appliances and certain floor finishes are often installed at the

factory.

17. After the modular units arrive, what work is left to complete the home?

First is the setting of the house on the foundation with a crane. Next is the erecting and unfolding of the roof system by the set crew. Utility connections must

be made. Electrical and mechanical system connections at marriage points between modules must be completed. Sometimes additional site work is required for

the construction of porches and decks. In many cases installation of siding and exterior trim, particularly for the unique custom home is required.

18. Can I buy a home directly from the Factory?

Most modular manufacturers sell only to the builder/dealer. You hire the Builder who then purchases the modules. Your contractual obligation is with the builder

not the factory. You may request the builder buy the modules from a factory of your choice. There are some factories that do sell directly to the consumer.

Yes. In this case however, the use of an architect is critical. We can create professional plans and layouts specific to your requirements. We will develop a look

that is stylistically correct creating the greatest resale value possible.

10. What styles of architecture can be created ?

Virtually all styles. Colonial, Victorian, Contemporary, Mediterranean, Avant garde Contemporary, Dutch colonial, Georgian, Shingle style and any other style

desired.

11. What kinds of materials can be specified ?

Nearly everything available in conventional building can be used in modular. If the factory can not get the product in time it can be installed on site.

12. Does union labor build modular homes ?

At many of the factories they do.

13. Are there any size limitations ?

No. The final design can be as big as you like. We developed a design for a 14,000 sf modular home comprised of thirty two modules units in Greenwich, CT.

Most large homes we design range in size from 4,000 to 6,000 sf, consisting of ten to twelve modules. Large open rooms are achieved by setting boxes side by

side, structured to provide an open and inviting living area.

14. Do modular homes have basements?

Yes. In addition, modular homes can be built over crawl spaces, on slabs or even on piles. These

foundation structures should be designed by a licensed architect or engineer.

15. How are the modular units shipped ?

The modules are shipped on carriers, towed by trucks. These trucks require 'wide load' escort vehicles. The modules are weather tight, wrapped in a waterproof

membrane.

16. How complete are they when they arrive at your site ?

As much as 80 to 85% complete. Most modules have interior walls and ceilings finished and primed, ready to receive paint. The electrical and plumbing systems

are installed. Windows, exterior and interior doors are hung, interior trim, cabinetry, toilet fixtures, appliances and certain floor finishes are often installed at the

factory.

17. After the modular units arrive, what work is left to complete the home?

First is the setting of the house on the foundation with a crane. Next is the erecting and unfolding of the roof system by the set crew. Utility connections must

be made. Electrical and mechanical system connections at marriage points between modules must be completed. Sometimes additional site work is required for

the construction of porches and decks. In many cases installation of siding and exterior trim, particularly for the unique custom home is required.

18. Can I buy a home directly from the Factory?

Most modular manufacturers sell only to the builder/dealer. You hire the Builder who then purchases the modules. Your contractual obligation is with the builder

not the factory. You may request the builder buy the modules from a factory of your choice. There are some factories that do sell directly to the consumer.

19. How does one get pricing on the modular home?

Generally the cost of the modular units, out of the factory, can vary from $ 75 to $ 100 a square foot depending on the level of finish and quality of fixtures

selected. Pricing can be affected by the geometric complexity of the architecture, region of the country you are building in and the complexity of the related

site work. Your Builder should be able to provide you with an accurate price quote based on your particular needs and wants.

Additional costs could include site inspection, excavation, foundation electrical and plumbing connections and all other site built amenities. In Fairfield County,

CT., a modular home could be built at a starting cost of $175 per square foot, "turn-key". These cost estimate will vary based on a variety of options and

construction labor costs for your particular area.

20. What is the customers' first step in building a modular home?

You should start with a design. Consider selecting a home from our collection or have a home custom designed by a design professional. We are a fully

licensed architectural firm available for this service. Once you have a design, a qualified builder/dealer should be contacted to prepare an accurate construction

cost estimate. Contact the factories in your area and ask them for a listing of builders for you to consider.

21. How do I buy a modular home?

If you like one of the stock designs from our “Cutler Series”, you may purchase the plans directly from our web site. Next, provide your builder a set of plans

so they can prepare an accurate construction cost estimate. Your Builder will submit our plans to the factory for pricing. After you sign a contract with your

Builder, he or she will process you home through the factory and purchase the modules on your behalf.

22. How does the builder get a building permit ?

Design drawings should be prepared by an architect from which shop drawings are generated by the factory. These plans are then reviewed, approved and

stamped by a third party engineering firm. Together with these plans, a foundation plan and any other drawings for conventionally built assemblies, your

Builder should submit for Building Permit issuance.

23. Can additions be done using modular building systems ?

Yes. We recommend hiring a licensed professional to examine the existing home and determine the feasibility of a modular addition. If existing conditions allow

for an addition, we suggest you work with an architect, experienced in modular technology, to assist you in creating a design that is not only functional but

increases the 'curb appeal' of your home. Our office is available for this service.

24. Can multi-family homes be built modular ?

Yes. We have examples available through our office.

25. Can commercial buildings as well?

Yes. We have some examples available through our office.

26. Where will the modular industry be in the future?

As this industry continues to develop their product for the mainstream market, they will refine the efficiency of the assembly line through automation.

Improving their production capability and product quality will reduce cost. This cost reduction will attract more builders, developers and ultimately the end

user/customer. Their product will be superior in price and quality gaining them a greater share of the home building market. The professional architect,

specializing in this industry, will create designs that appeal to a broader market. One day, this industry will become design driven similar to the fashion,

furniture and automotive industries.

Generally the cost of the modular units, out of the factory, can vary from $ 75 to $ 100 a square foot depending on the level of finish and quality of fixtures

selected. Pricing can be affected by the geometric complexity of the architecture, region of the country you are building in and the complexity of the related

site work. Your Builder should be able to provide you with an accurate price quote based on your particular needs and wants.

Additional costs could include site inspection, excavation, foundation electrical and plumbing connections and all other site built amenities. In Fairfield County,

CT., a modular home could be built at a starting cost of $175 per square foot, "turn-key". These cost estimate will vary based on a variety of options and

construction labor costs for your particular area.

20. What is the customers' first step in building a modular home?

You should start with a design. Consider selecting a home from our collection or have a home custom designed by a design professional. We are a fully

licensed architectural firm available for this service. Once you have a design, a qualified builder/dealer should be contacted to prepare an accurate construction

cost estimate. Contact the factories in your area and ask them for a listing of builders for you to consider.

21. How do I buy a modular home?

If you like one of the stock designs from our “Cutler Series”, you may purchase the plans directly from our web site. Next, provide your builder a set of plans

so they can prepare an accurate construction cost estimate. Your Builder will submit our plans to the factory for pricing. After you sign a contract with your

Builder, he or she will process you home through the factory and purchase the modules on your behalf.

22. How does the builder get a building permit ?

Design drawings should be prepared by an architect from which shop drawings are generated by the factory. These plans are then reviewed, approved and

stamped by a third party engineering firm. Together with these plans, a foundation plan and any other drawings for conventionally built assemblies, your

Builder should submit for Building Permit issuance.

23. Can additions be done using modular building systems ?

Yes. We recommend hiring a licensed professional to examine the existing home and determine the feasibility of a modular addition. If existing conditions allow

for an addition, we suggest you work with an architect, experienced in modular technology, to assist you in creating a design that is not only functional but

increases the 'curb appeal' of your home. Our office is available for this service.

24. Can multi-family homes be built modular ?

Yes. We have examples available through our office.

25. Can commercial buildings as well?

Yes. We have some examples available through our office.

26. Where will the modular industry be in the future?

As this industry continues to develop their product for the mainstream market, they will refine the efficiency of the assembly line through automation.

Improving their production capability and product quality will reduce cost. This cost reduction will attract more builders, developers and ultimately the end

user/customer. Their product will be superior in price and quality gaining them a greater share of the home building market. The professional architect,

specializing in this industry, will create designs that appeal to a broader market. One day, this industry will become design driven similar to the fashion,

furniture and automotive industries.

| Why Modular CONTRARY TO THE MYTHS ABOUT MODULAR HOMES SPOKEN PRIMARILY BY THOSE WHO WISH THE MYTHS WERE TRUE: FACTORY-BUILT HOMES HAVE SUPERIOR QUALITY. Regardless of whether we're talking about factory-built, panelized or modular homes, in-plant construction quality is invariably superior to what can be done on a job site. Parts cut with a hand saw or a hand-held power circular saw at a job site cannot possibly be as precise as those cut with a $10,000 radial arm saw or $100,000 component cutter in a factory. Factory fastening methods are also demonstrably superior because they use pneumatic tools, which drive fasteners to precise depths - no under-driving and no shiners. What's more, factory inspections cover every construction detail from floor framing to final paint, and trained factory inspectors or independent third party inspectors perform more than one-dozen unannounced inspections per house. The best that can be hoped for at a job site is three or four announced inspections. These days, with so much construction going on, local inspectors don't always have time to get there. |

FACTORY-BUILT MATERIALS ARE THE BEST.

The quality modular home manufacturer does not use green

lumber and protects all building materials from the weather;

otherwise, materials would be too warped or bent to fit into

their precise jigs for wall panels or trusses. In many on-site

building locations either green lumber is still used or building

materials are not protected from the weather; as a result, for

decades the ultimate homeowner inherits problems after the

building is finished.

FACTORY-BUILT HOMES ARE STRONGER THAN

STICK BUILT HOMES.

The modular unit uses the strongest of all construction

methods based on the 2x6 platform framing system.

Traditionally, modular units are over-built so they can be

hauled on wheels over roads to get to the site and so that a

crane can lift them off the wheels and place them on a

foundation. Only modular construction is sturdy enough to

withstand such forces which are the equivalent to that of a

healthy earthquake.

FACTORY-BUILT HOMES ARE EASIER TO FINANCE.

Factory-built homes are very easy to finance because they

have a positive track record. When the homeowner wants, for

instance, the Acme Plan 3A from a factory with some

variations, chances are the local banker has seen it before and

knows the value. Bankers also like the idea that factory-built

homes are well insulated which means the ultimate buyer

won't go broke paying utility bills. Bankers also like the

simplicity of the construction process compared to on-site

construction.

FACTORY-BUILT HOMES ARE QUICKER TO BUILD.

From the time you place your order, even when the factory is

hopping busy, you can get a two-module home delivered to

your site in eight weeks or less and you can move into it

within a few more weeks. From the time you place your

order, the average site built home takes six to nine months to

complete.

The quality modular home manufacturer does not use green

lumber and protects all building materials from the weather;

otherwise, materials would be too warped or bent to fit into

their precise jigs for wall panels or trusses. In many on-site

building locations either green lumber is still used or building

materials are not protected from the weather; as a result, for

decades the ultimate homeowner inherits problems after the

building is finished.

FACTORY-BUILT HOMES ARE STRONGER THAN

STICK BUILT HOMES.

The modular unit uses the strongest of all construction

methods based on the 2x6 platform framing system.

Traditionally, modular units are over-built so they can be

hauled on wheels over roads to get to the site and so that a

crane can lift them off the wheels and place them on a

foundation. Only modular construction is sturdy enough to

withstand such forces which are the equivalent to that of a

healthy earthquake.

FACTORY-BUILT HOMES ARE EASIER TO FINANCE.

Factory-built homes are very easy to finance because they

have a positive track record. When the homeowner wants, for

instance, the Acme Plan 3A from a factory with some

variations, chances are the local banker has seen it before and

knows the value. Bankers also like the idea that factory-built

homes are well insulated which means the ultimate buyer

won't go broke paying utility bills. Bankers also like the

simplicity of the construction process compared to on-site

construction.

FACTORY-BUILT HOMES ARE QUICKER TO BUILD.

From the time you place your order, even when the factory is

hopping busy, you can get a two-module home delivered to

your site in eight weeks or less and you can move into it

within a few more weeks. From the time you place your

order, the average site built home takes six to nine months to

complete.

| Licensed In Architecture for the Major Metropolitan areas of New York, New Jersey, Connecticut and Pennsylvania. More than 17 Years Experience. We specialize in custom modular home designs... Why Modular versus a factory built home? More Value & Higher Quality Over 40 designs |

| Interested? Contact the publisher: jsebastian@thenewyorkoptimist.com |

| © MMVIII, . All Rights Reserved. The New York Optimist & www.thenewyorkoptimist.com is a registered trademark of . The New York Optimist is a registered service mark of Thenewyorkoptimist.com. The New York Optimist logo and original photos are a registered trademark of The New York Optimist. All other photos are property of the advertiser. And are rightfully protected under their copywright protections. |

SHARE

| The New York Optimist |

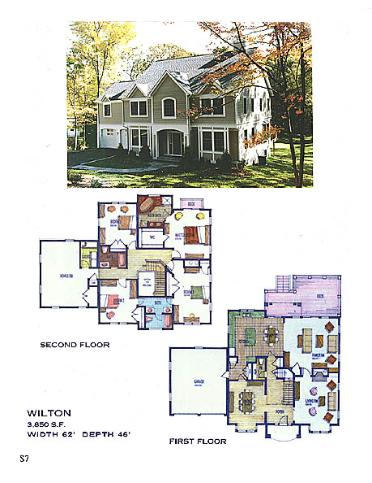

Douglas Cutler gives a tour of his stunning modular home in Wilton,

CT. He explains how building a modular home saved him about

$250,000 in building costs. More of his homes can be found at

http://www.modulararchitecture.com/

CT. He explains how building a modular home saved him about

$250,000 in building costs. More of his homes can be found at

http://www.modulararchitecture.com/